4 Qualities to Look For in Your Next Electronics Contract Manufacturer

Farming out your production to an outside electronics contract manufacturer (CM) can help you produce and sell products without having to invest in machinery, equipment or specialized product knowledge. For a price, contract manufacturing relieves the hiring OEM company from the burden of hiring production staff, purchasing machinery, investing in industry knowledge and much more.

Advantages of Using a Quality Electronics Contract Manufacturer

OEM companies often choose contract manufacturing to make it easier, less expensive and more efficient to bring new products to the market. Here are a few of the obvious benefits of working with a CM:

Focus on Core Competencies

Contract manufacturing frees up man power at the hiring OEM companies; allowing them to stay focused on their strengths and core competencies of sales and marketing.

Cost Saving Strategies

OEM companies can achieve cost savings by contracting manufacturers that already have knowledge of the manufacturing process, have invested in the appropriate equipment, and run similar but non-competing products in their facilities, can help take advantage of economies of scale due to their high experience and knowledge.

Supply Chain Management

Gaining access to qualified suppliers globally, component engineering, obsolescence and alternate component identification plus total landed cost analysis, eliminates the need for in-house staff. CMs can also drop-ship your product directly to your consumer or to a specified geographic area clearing the need of investing in warehouses.

Prerequisites of a Quality Electronics Contract Manufacturer

In addition to the obvious advantages stated above, to design a game plan for success there are at least 4 more critical issues for an OEM to consider while working with an electronics CM.

Engineering Design Services

You may choose to design the electronics and software that is complex and/or involves substantial IP, but ask the CM to handle the design of the “non-core” electronics, enclosures, plastics and other components.

Manufacturing Tooling Design

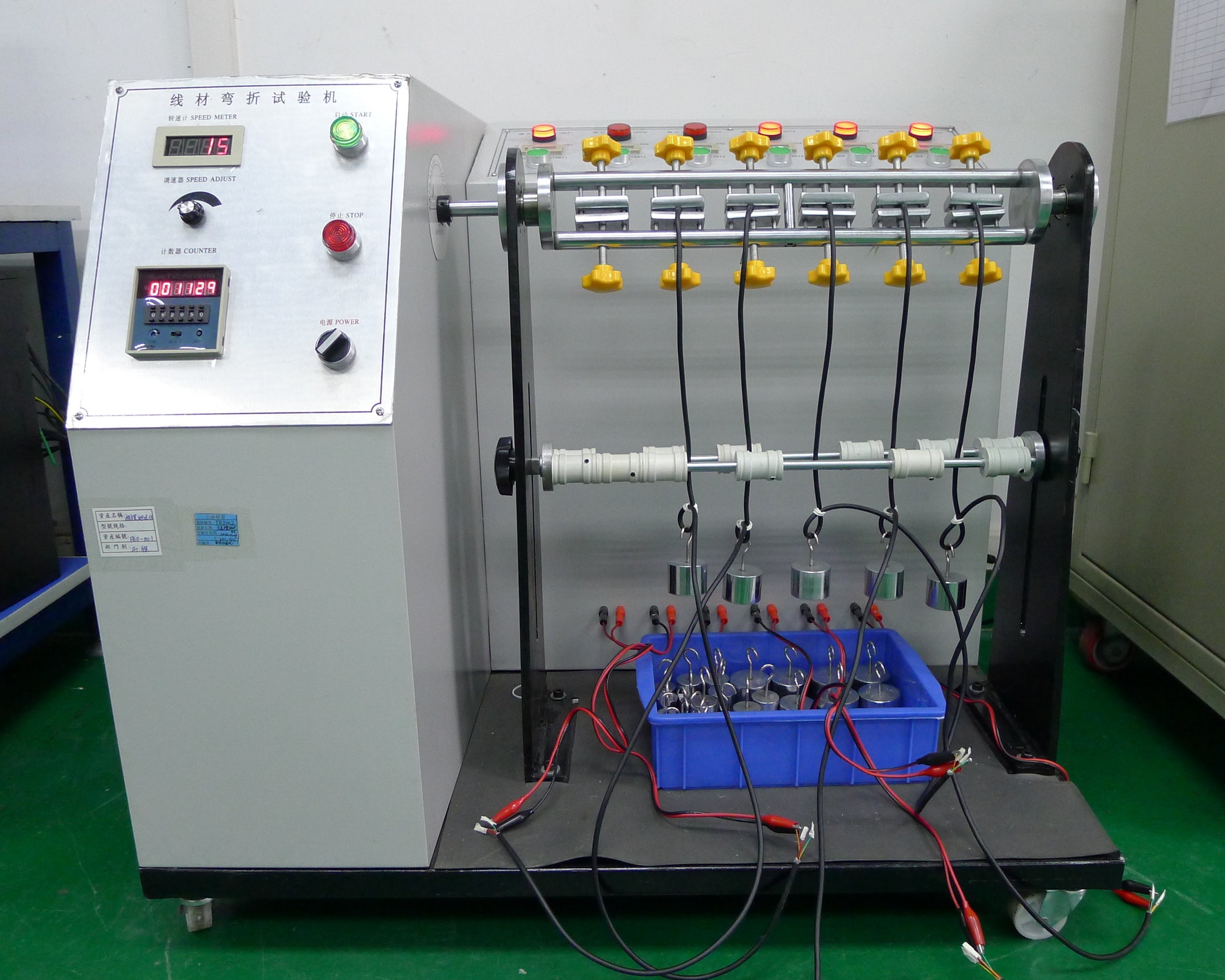

Make sure your CM is able to assist with every aspect of the product launch, including the development of manufacturing tooling, hard tools for metal fabrication and plastic injection molding, as well as a wide variety of in-circuit and functional test tools.

Product Introduction & Production Ramp-up Expertise

Through many years of experience, your manufacturing partner should have refined the business processes to have the ability to introduce and ramp-up production to volume when needed.

Last, but not the least,

Solving Your Specific Production Issues

Like they say, “the proof of the pudding is in the eating”, let’s face it, if they are not willing or able to address your specific problems and concerns, it doesn’t matter how clever a CM can be, it is still of little or no value to you. Make sure your partner specializes in manufacturing complex electro-mechanical products which will in turn be of the most benefit to your product development.

Learn More About Electronics Contract Manufacturing:

3 Ways A Contract Manufacturer Can Benefit Your Business

Learn more about the perks an electronics contract manufacturer can offer your product.

Need help finding an outsourcing manufacturing partner?

Send our experts a message so we can help.

Enjoyed this article? Don't forget to share.